Maintenance and Material Management

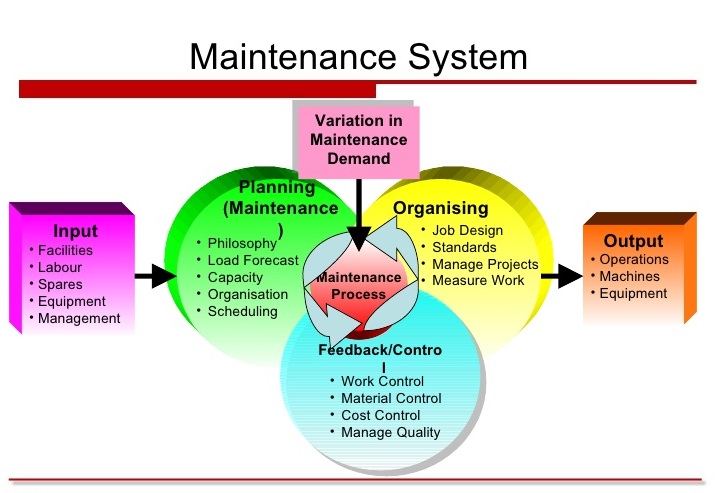

The Standard Navy Maintenance and Material Management Systems (3-M) was developed to meet the need for a more effective means of recording, reporting, and evaluating the maintenance requirements of the fleet. In the past, most maintenance work was recorded only in the shipboard logs. Although some reports were required for failures of specified electronic equipment systems and components, material commands had noway of knowing if maintenance was being performed on equipment under their cognizance. There was also a lack of financial information. There was no effective way of determining what part of the ship’s operating target (OPTAR) was being spent for repair parts and how much for consumable material.

These needs were partially met by using different fund codes for the different classifications of material.For example, Equipage, Repair parts, and Consumables. Commands were then able to evaluate OPTAR usage. It was not until the advent of the Maintenance Data System (MDS) that cognizant commands could determine where maintenance man-hours and materials were being used and there by evaluate the performance of equipment.

While 3-M and MDS are primarily the responsibility of other departments supply does have a definite part in making MDS work. This chapter discusses the general concept of the shipboard 3-M Systems and your responsibility in the overall effectiveness of the program.

The 3-M Systems

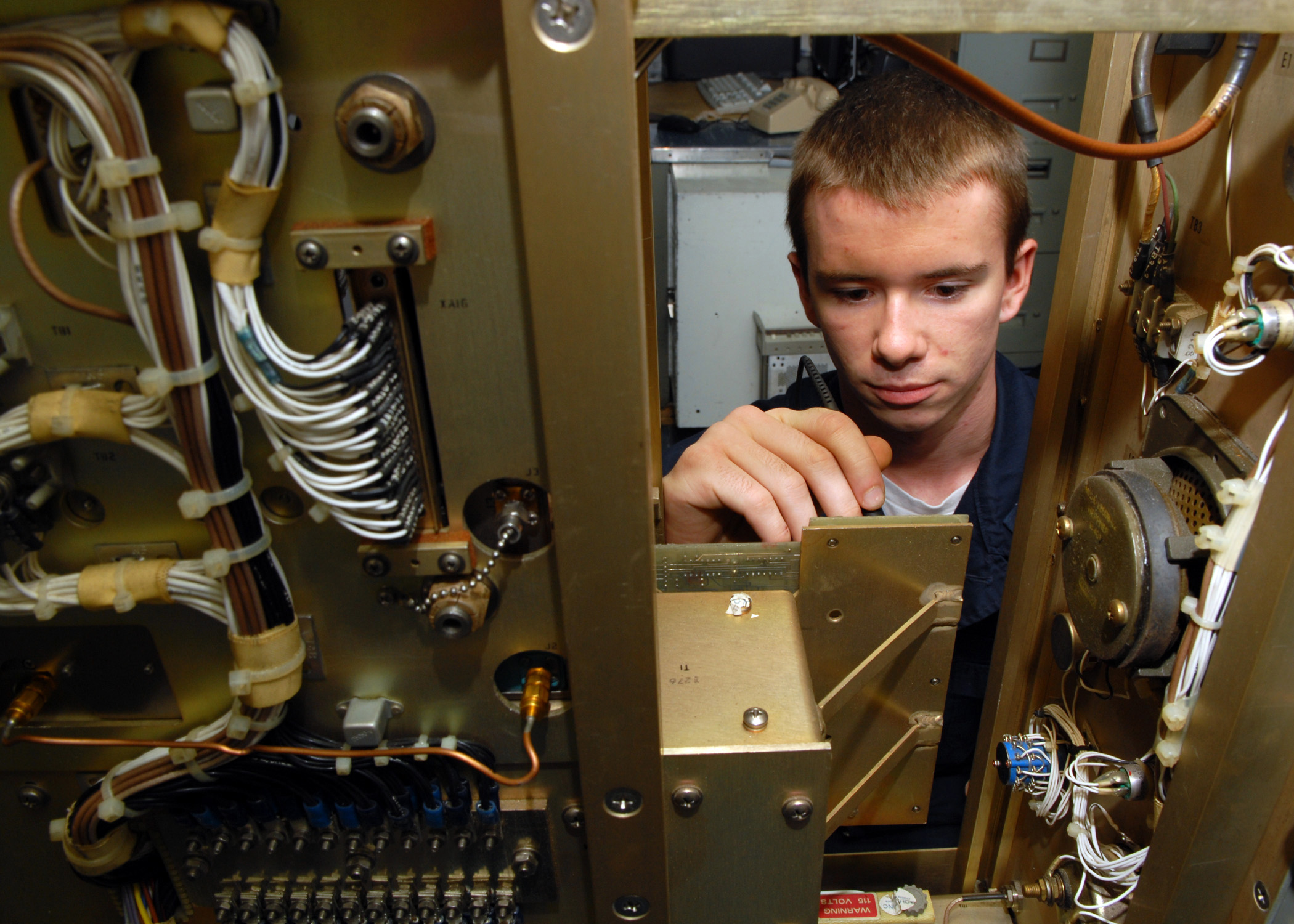

Each year, newly developed equipments requiring highly specialized maintenance are installed aboard the Navy’s ships.The maintenance requirements for an electric motor or a circulating pump are relatively few and simple.This is because of simplicity of design, a small number of moving parts, and the fact that several person may be qualified to perform the maintenance work.This is not the case for automatic engineering controls or the computers used for the control or missile guidance systems. To perform properly, these control systems must react immediately and accurately to changing conditions. The 3-M systems endeavor to substitute preventive maintenance for corrective maintenance, thus reducing equipment malfunction and downtime.

Proper evaluation of equipment cannot be based only on planned exercises when all possible preparations are made ahead of time. The 3-M systems provide a means of continuously reporting maintenance actions, equipment downtime, repair parts used, and the maintenance personnel required to perform the work,(Equipment downtime is he amount of time an equipment is inoperable due to performance of maintenance, lack of repair parts to fix it, or repair is beyond the capability of ship’s personnel.) The 3-M systems is not limited to complex systems. It is equally applicable to, and effective for all types of shipboard equipment.

The ship’s 3-M systems consist of the following systems designed for maintenance management :

- PMS (Planned Maintenance System)

—Inactive Equipment Maintenance (IEM)

- MDS (Maintenance Data System)

—AMS (Alteration Management System)

—IMMS (Intermediate Maintenance Activity Maintenance Management System)

The scope of these systems of most importance to the SK3 and SK2 is described in the following sub paragraphs.